"SiteWatch 360’s Energy Management System was made for energy efficiency projects. It helps identify the best opportunities and creates the benchmarking, verification and ROI data to justify the projects and apply for the rebates!" — Energy Efficiency Engineer

SiteWatch 360 is the #1 solution for continuously monitoring any type of data in a factory or commercial building — easily up-and-running in 30 days, using leading-edge IOT technology to provide the lowest cost end-to-end solution you can buy.

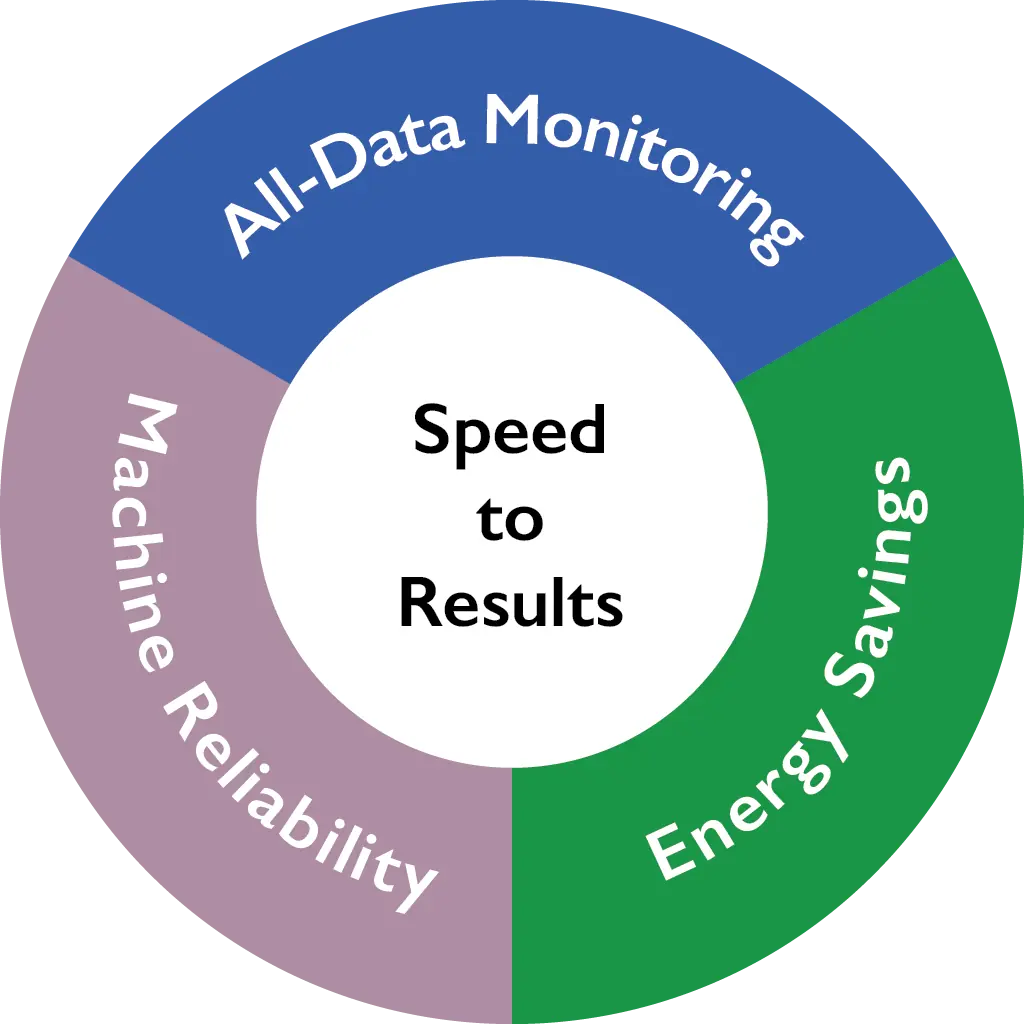

SiteWatch 360 provides a comprehensive suite of intelligent monitoring services that include…

Manufacturers need to monitor many different variables, so SiteWatch 360 was designed to capture and transmit any variable, which can then be analyzed and converted into useful/actionable information to improve plant operations. Real-time operating data can be captured from a single machine, multiple machines, a whole production line, or multiple facilities globally.

SiteWatch 360 provides plant engineers with a unique solution for optimizing machine maintenance intervals by supplying real-time and historic load information, since higher loading means more stress on a machine, often leading to premature failure.

SiteWatch 360 identifies wasted energy from excessive machine runtime, optimizing machine settings and eliminating mechanical inefficiencies, as well as reducing peak energy demand relative to plant output. You can't save energy if you don't know where you're wasting it — where, when and how much. Energy bills can be reduced by lowering total usage in kWh (about ⅔ of your bill) and peak demand in kW (about ⅓ of your bill).

Leading-edge IOT technology utilizes self-powered clip-on sensors which are fast and easy to install — up to 50+ machines in a day. SiteWatch 360 can be fully up and running within a few days of your ‘go-ahead’, including user training on our easy-to-use software platform.

How SiteWatch 360 Helps Achieve a Rapid Payback

- Self-powered sensors — clip-on and can be installed on 50+ machines in a single day. Fully up-and-running system within 2 weeks.

- Hands-on installation assistance and training available.

- Easy-to-use analytical software is highly flexible and can be readily modified for your specific needs.

- Energy and reliability engineering assistance available from our experienced engineers. This includes…

- Regular data reviews. Despite the best of intentions, hardly anybody has time to review their own data in detail. We set up a schedule for joint web meetings with your team to review what your data is revealing.

- ‘Instant’ energy audits. Once our sensors are installed you can do an energy audit at the click of a button.

- M&V for energy-efficiency investments. Detailed real-time usage data will support accurate payback and ROI calculations.

SiteWatch 360 is the Swiss-Army-Knife of real-time monitoring and measurement. We can track almost any variable in a factory or commercial building, in addition to providing…

- Multi-variable ‘compound’ alerting, which assists with machine-failure-warning and avoiding downtime.

- Tariff engine — provides accurate on-peak, off peak and mid-peak costing for utility use, rather than flat rates.

- Custom reports and custom dashboards can be readily built to match your precise information requirements.

- Open platform imports from, and exports to, most other BMS or SCADA systems.

Meeting compliance requirements. Our energy engineers can help create (one-click) repeatable reports assist with a variety of compliance issues…

- Energy waste reduction. You can't save energy if you don't know where, when and how you're wasting it.

- Environmental compliance — e.g., emissions of all types.

- ESG, ISO and carbon footprint reporting.

- Local law requirements for commercial buildings in about 30 US cities — where building owners must measure and reduce energy-use if building is >50,000 sq. ft.

SiteWatch 360's ROI is rapid because there are many opportunities to save money in any facility if you know where you're wasting it. The cost of our system is very low and there are rebates and incentives available from most utilities that help reduce the cost further.