"The SiteWatch 360 EnMS helps me be more effective and efficient in managing our energy spend by having visibility into electricity, natural gas and water usage all on one platform!" — CIO, Packaging Industry

SiteWatch 360 is the most comprehensive, cost-effective energy-management and machine-reliability solution available in the market today. Consider these factors:

All Data Types

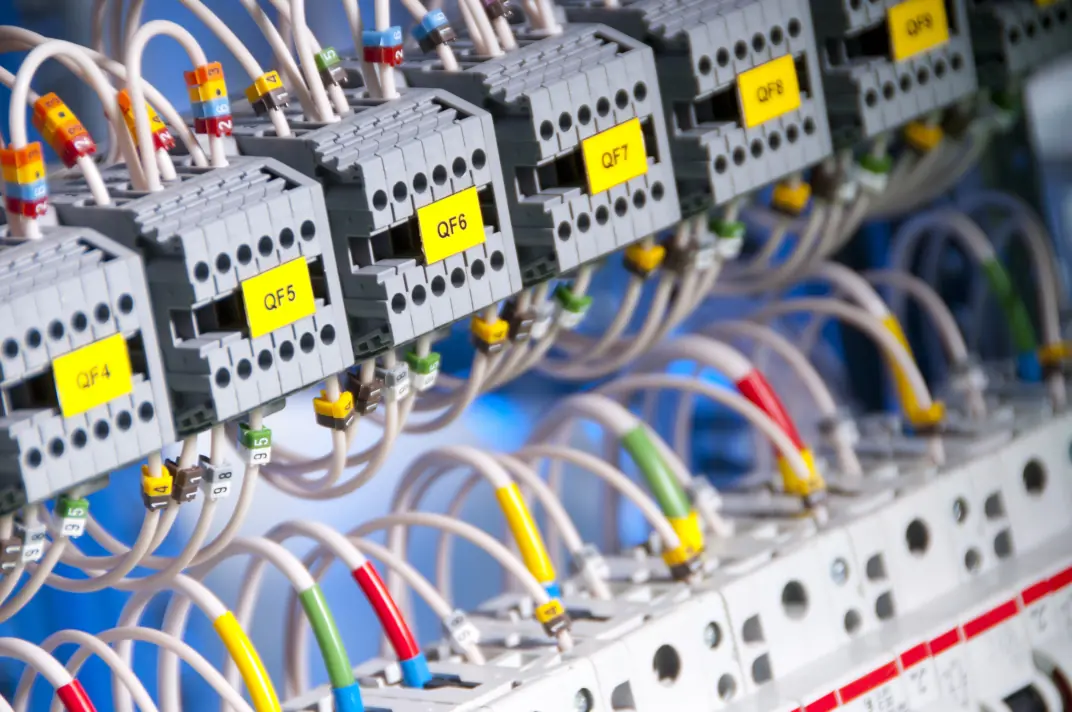

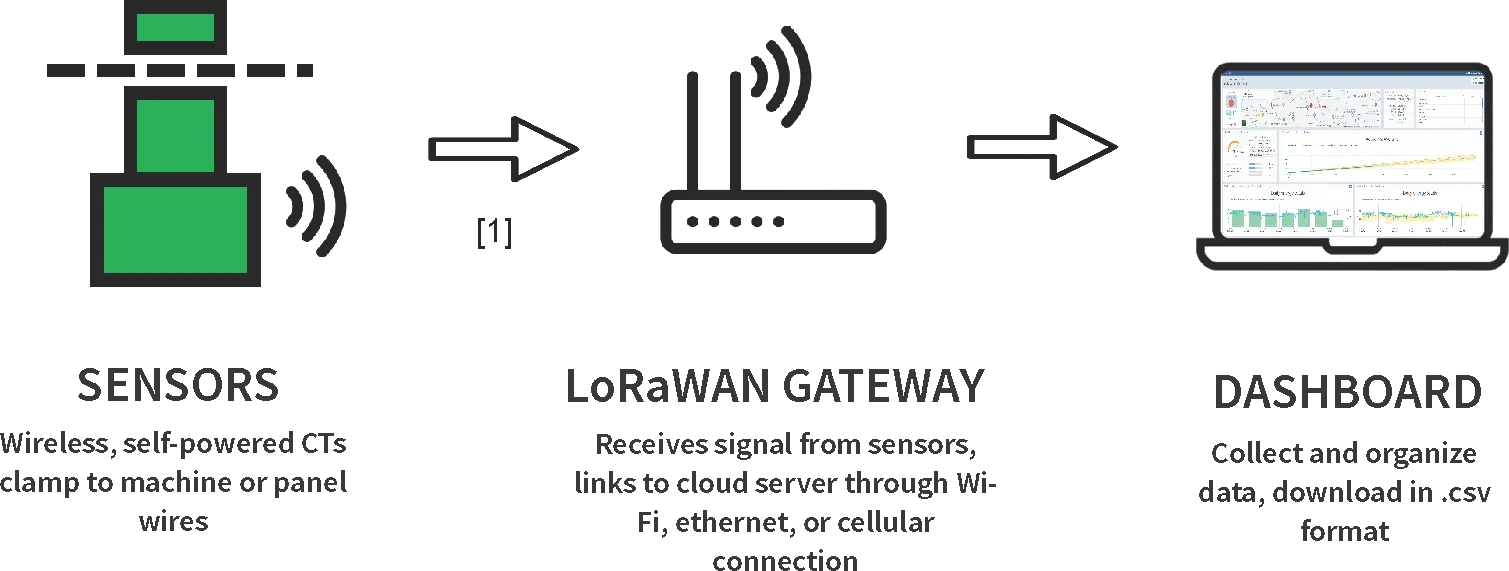

SiteWatch 360 uses an array of sensors to capture data. For electricity monitoring, we have clip-on LoRa-enabled sensors — for rapid installation — for customers who already have LoRa Networks in their facility or who require long-distance transmission. They are self-powered, harvesting sufficient power to transmit png distances from the magnetic filed created by the current passing through the wire, so they don't need any external power source.

In addition, SiteWatch 360 can also capture non-electricity data from any type or brand of sensor or meter (e.g., temperature, pressure, humidity, CO2, emissions, liquid levels, vibration) — no matter the manufacturer. All data — both electricity and non-electricity — can be transmitted to, stored, and analyzed by our SiteWatch 360 software platform. View typical data that users want to monitor…

Fast, Simple Installation

IOT technology has transformed our ability to capture and transmit data wirelessly, from the sensors to the gateway via LoraWAN, with onward transmission to our cloud via Wi-Fi or cellular connection.

Installation is fast and simple for both, with the results visible within minutes of installation. Using the clip-on sensors, we can install sensors on 50+ machines in a single day, often without powering down the equipment or the power panels. Data flows immediately.

Secure Communication

Each group of sensors communicates with a gateway (a type of router) via LoraWan. Then gateways communicate directly with the cloud via WiFi, ethernet or cellularly, effectively eliminating IT security concerns.

Captured data is consolidated in the cloud, enabling detailed analysis of energy consumption, as well as data from Building Management Systems, or other legacy systems. Once analyzed, the data is presented to users as actionable real-time graphs, heat maps, reports and alerts — showing precisely what's happening in your facility at any time.

Long Range

LoRa devices have a considerable range of about 10 miles with no obstacles and about 3 miles within a busy area like a city. Within a building, their range can vary from 200-300 feet up to 700-800 ft depending on the construction and layout of the building. LoRa has much lower throughput than Bluetooth or Wi-Fi, however, which makes it ideal for transmitting relatively small amounts of power data within a factory or campus.

Upfront and Ongoing Engineering Support

We assign a two-person team to each customer, comprising a Professional Engineer and a Project Manager. They work with your team to define the project (scoping), supervise onsite installation of the hardware, train your personnel, and help set up the graphs, charts, reports and alerts to your requirements in the software.

There is no ‘per seat’ charge for the software, so your entire team can view the appropriate reports and alerts on their desktop, laptop, or mobile device.

Importantly, our engineers do not “disappear” after installation: our team remains involved with you, providing ongoing support through monthly reports and quarterly or semi-annual reviews designed to turn data into easily-understandable and actionable information resulting in energy savings and more reliable equipment.

Next Steps

SiteWatch 360 was designed and priced for any size of organization — small, medium or large. Since our monitoring sensors can simply be snapped onto or off a circuit in minutes, it's fast and easy to make installations from 1 sensor to 1000 or more sensors. Also, because SiteWatch 360 is a cloud-based service, the cost of the sensors, installation, and training is remarkably low and most utility companies offer rebates and incentives to lower the cost even further.

To complete a SiteWatch 360 installation you do not need the help of system integrators, automation consultants or software developers. Our engineers will guide you through our simple hardware installation process and will train your personnel in how to use our comprehensive software platform. Any specialized/unique changes to our software platform can be made by our developers within a few days.

To start the process and give you a firm proposal/quote, we need to know how many and what kind of machines you want to monitor, and then a minimal amount of information such as the number of motors you want to monitor, their geographical location within your facility, and their Full Load Amp ratings and wire sizes.